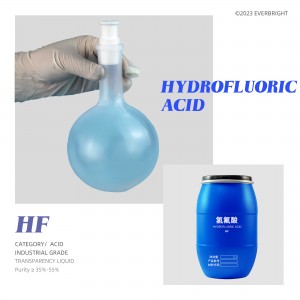

HYDROFLUORIC ACID / HF

SPECIFICATIONS muab

Transparency kua Purity ≥ 35% -55%

EVERBRIGHT® ' kuj tseem yuav muab kev kho kom haum:

cov ntsiab lus / whiteness / particlesize / PHvalue / xim / ntim style / ntim specifications

thiab lwm yam khoom tshwj xeeb uas tsim nyog rau koj cov kev siv, thiab muab cov qauv dawb.

KHOOM NTAUB NTAWV

Hydrogen fluoride gas yog soluble hauv dej, thiab nws cov kua dej hu uahydrofluoric acid.Cov khoom yog feem ntau 35% -50% aqueous tov ntawm hydrogen fluoride gas, qhov siab tshaj plaws concentration yuav ncav cuag 75%, thiab nws yog ib tug tsis muaj kob thiab hais meej haus luam yeeb kua.Pungent tsw, volatile, dawb pa luam yeeb nyob rau hauv cov huab cua.Nws yog ib qho nruab nrab lub zog inorganic acid, corrosive heev, thiab tuaj yeem ua rau iav thiab silicates los tsim gaseous silicon tetrafluoride.Nws tuaj yeem cuam tshuam nrog cov hlau, hlau oxides thiab hydroxides los tsim ntau cov ntsev, tab sis cov nyhuv tsis yog khaus li hydrochloric acid.Kub, platinum, txhuas, paraffin thiab qee cov yas tsis ua haujlwm nrog nws, yog li cov thawv tuaj yeem ua tau.Hydrogen fluoride gas yog yooj yim rau polymerize, tsim (HF) 2 (HF) 3 · · iso-chain molecules, nyob rau hauv cov kua hauv lub xeev, cov degree ntawm polymerization nce.Khaws rau hauv cov thawv uas ua los ntawm txhuas, siv quav ciab lossis yas.Nws yog heev toxicity thiab ulcerates ntawm daim tawv nqaij.

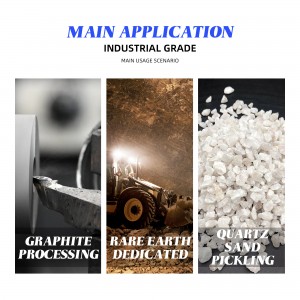

KHOOM SIV

QIB INDUSTRIAL

Graphite processing

Hydrofluoric acid yog cov kua qaub uas muaj zog uas tuaj yeem ua rau yuav luag txhua qhov impurities hauv graphite, thiab graphite muaj cov kua qaub zoo, tshwj xeeb tshaj yog tuaj yeem tiv taus hydrofluoric acid, uas txiav txim siab tias graphite tuaj yeem ntxuav nrog hydrofluoric acid.Cov txheej txheem tseem ceeb ntawm txoj kev hydrofluoric acid yog kev sib xyaw ntawm graphite thiab hydrofluoric acid, thiab cov tshuaj tiv thaiv ntawm hydrofluoric acid thiab impurities rau ib lub sij hawm los tsim cov tshuaj soluble lossis volatiles, tom qab ntxuav kom tshem tawm impurities, lub cev qhuav dej thiab ziab kom tau purified graphite.

Rare ntiaj teb Dedicated

Kev npaj ntawm anhydrous rare earth fluoride yog los ntawm nag lossis daus ntawm hydrated tsawg lub ntiaj teb fluoride los ntawm cov kua dej, ces lub cev qhuav dej, los yog ncaj qha fluorination ntawm tsawg ntiaj teb oxides nrog fluorinating agents.Lub solubility ntawm lub ntiaj teb tsis tshua muaj fluoride yog me me, thiab kev siv cov hydrofluoric acid tuaj yeem ua rau nws los ntawm hydrochloric acid, sulfuric acid los yog nitric acid tov ntawm lub ntiaj teb tsis tshua muaj (lub precipitate yog nyob rau hauv daim ntawv ntawm hydrated fluoride).

Hlau nto kho

Tshem tawm cov pa oxygen-muaj impurities Hydrofluoric acid yog cov kua qaub tsis muaj zog, zoo ib yam li lub zog rau formic acid.Qhov dav dav ntawm cov khoom lag luam muaj hydrofluoric acid yog 30% txog 50%.Cov yam ntxwv tseem ceeb ntawm hydrofluoric acid tshem tawm xeb yog raws li hauv qab no: (1) Muaj peev xwm yaj cov silicon-muaj cov sib txuas, txhuas, chromium thiab lwm yam hlau oxides kuj muaj cov solubility zoo, feem ntau siv rau etch castings, stainless hlau thiab lwm yam workpieces.(2) Rau steel thiab hlau workpieces, tsis tshua muaj concentration hydrofluoric acid tuaj yeem siv rau kev tshem tawm xeb.Aqueous tov ntawm hydrofluoric acid nrog ib tug concentration ntawm 70% muaj passivation nyhuv ntawm hlau (3) Hydrofluoric acid nrog ib tug concentration ntawm txog 10% muaj ib tug tsis muaj zog corrosion ntawm magnesium thiab nws alloys, yog li nws yog feem ntau siv rau etching ntawm magnesium workpieces.(4) txhuas feem ntau tsis corroded los ntawm hydrofluoric acid;Nickel muaj zog tiv thaiv nyob rau hauv hydrofluoric acid daws nrog ntau dua 60%.Hydrofluoric acid yog cov tshuaj lom heev, thiab volatile, thaum siv los tiv thaiv tib neeg kev sib cuag nrog hydrofluoric acid kua thiab hydrogen fluoride gas, lub tank etching yog zoo tshaj plaws kaw thiab muaj ib tug zoo cua tshuab, fluorinated dej khib nyiab tuaj yeem tawm tom qab kev kho mob.

Quartz xuab zeb pickling

Nws ua haujlwm zoo tshaj plaws thaum kho nrog hydrofluoric acid, tab sis yuav tsum muaj ntau dua concentration.Thaum sib koom nrog sodium dithionite, txo qis ntawm hydrofluoric acid tuaj yeem siv tau.Ib qho concentration ntawm hydrochloric acid thiab hydrofluoric acid tov tau tov rau hauv quartz xuab zeb slurry tib lub sijhawm raws li qhov kev faib ua feem;Nws tseem tuaj yeem kho nrog cov tshuaj hydrochloric acid ua ntej, ntxuav thiab tom qab ntawd kho nrog hydrofluoric acid, kho ntawm qhov kub thiab txias rau 2-3 teev, thiab tom qab ntawd lim thiab ntxuav Cov impurities thiab oxides ntawm cov xuab zeb quartz tuaj yeem raug tshem tawm zoo, thiab purity thiab zoo ntawm quartz xuab zeb tuaj yeem txhim kho.

FOCS Fiber corrosion kuj

Hydrofluoric acid filling corrosion ntawm photonic siv lead ua fiber (PCF) tau tsim.Hydrofluoric acid tau ntim rau hauv lub qhov cua ntawm kos photonic crystal fiber.Los ntawm kev hloov nws cov qauv ntoo khaub lig, photonic siv lead ua fiber ntau nrog cov qauv tshwj xeeb tau tsim los hloov nws lub teeb conductivity.Cov txiaj ntsig tau pom tias qhov xau poob thiab tawg poob qis nrog qhov corrosion degree ntawm huab cua qhov ntawm photonic siv lead ua fiber ntau, cov nonlinear coefficient nce pom tseeb, qhov ua tau zoo refractive Performance index ntawm hom tseem ceeb thiab qhov sib npaug refractive index ntawm cladding txo qhov sib npaug, thiab pab pawg tshaj tawm dispersion kuj hloov.

ELECTRONIC Qib

TPT-LCD npo thinning

Nyob rau hauv kev tiv thaiv ntawm photoresist thiab ciam teb kua nplaum, lub concentration ntawm hydrofluoric acid yog hloov, ib tug tej yam nqi ntawm nitric acid, concentrated sulfuric acid thiab hydrochloric acid yog ntxiv, thiab cov ultrasonic auxiliary tej yam kev mob ntxiv, tus nqi etching yog obviously txhim kho.Qhov saum npoo roughness raug txo kom zoo los ntawm kev hloov cov txheej txheem ntxuav, thiab nag lossis daus ntawm cov ntaub nplaum dawb yog txo.daws qhov teeb meem ntawm ntxhib nto thiab dawb nto adhesion precipitate.